1. Kev kho ntawm lub hauv paus phab ntsa thiab nws cov cement mortar leveling txheej thiab installation ntawm embedded qhov chaw tau ua tiav.Cov khoom siv tsim nyog thiab cov khoom siv tiv thaiv kev ua haujlwm yuav tsum npaj txhij.Qhov tshwj xeeb scaffolding rau kev tsim kho yuav tsum tau txhim kho kom ruaj khov thiab dhau qhov kev soj ntsuam kev nyab xeeb.Qhov kev ncua deb ntawm cov ncej scaffolding thiab kab rov tav ncej thiab phab ntsa thiab cov ces kaum yuav tsum ua tau raws li qhov yuav tsum tau ua.

2. Lub hauv paus phab ntsa yuav tsum muaj zog thiab tiaj tus, thiab saum npoo yuav tsum qhuav, tsis muaj cracking, hollowing, looseness los yog efflorescence.Lub zog sib txuas, flatness thiab verticality ntawm cov cement mortar leveling txheej yuav tsum ua raws li (Code rau Kev Txais Lub Tsev Kho Kom Zoo Nkauj Engineering Zoo) GB50210 Cov Lus Qhia rau qhov zoo ntawm cov txheej txheem plastering zoo tib yam.

3.Thaum kev tsim kho ntawm sab nraud thermal rwb thaiv tsev ntawmpob zeb woolboard, lub hauv paus chav kawm thiab kev tsim kho ib puag ncig kub yuav tsum tsis txhob tsim thaum kub qis dua 5 ℃.Kev tsim kho tsis raug tso cai nyob rau hauv cua daj cua dub thiab nag thiab daus huab cua saum qib tsib.Thaum lub sij hawm thiab tom qab kev tsim kho, kev ntsuas zoo yuav tsum tau coj los tiv thaiv kev yaig los nag thiab tshav ntuj kub, thiab yuav tsum tau ua cov txheej txheem tiv thaiv raws sijhawm.Yog tias nag los nag thaum lub sijhawm tsim kho, kev ntsuas yuav tsum tau coj los tiv thaiv cov dej nag los ntawm kev ntxuav cov phab ntsa;Thaum lub caij ntuj no kev tsim kho, kev tiv thaiv kev tiv thaiv yuav tsum tau ua raws li cov qauv tsim nyog.

4. Ua ntej kev tsim kho loj, cov khoom siv tib yam, kev tsim kho thiab kev tsim khoom siv tes ua yuav tsum tau siv rau ntawm qhov chaw los ua qauv phab ntsa raws li cov kev cai, thiab kev tsim kho tsuas yog ua tau tom qab kev pom zoo los ntawm cov neeg koom nrog.Thaum sivpob zeb woolboard rau kev tsim kho, tus neeg teb xov tooj yuav tsum hnav cov cuab yeej tiv thaiv, ua haujlwm zoo ntawm kev tiv thaiv kev noj qab haus huv, thiab xyuam xim rau kev tsim kho kev nyab xeeb.

5. Cov ntaub ntawv uas yuav tsum tau soj ntsuam rau sab nraud thermal rwb thaiv tsev system ntawmpob zeb woollub rooj tsavxwm yuav tsum raug xa mus rau lub koom haum kuaj kev tsim nyog rau kev sim, thiab tuaj yeem siv tsuas yog tom qab qhov kev xeem tau tsim nyog.Txoj kev sticking los yog point sticking method yuav tsum tau saws los lo raupob zeb woolboard, thiab cov kua nplaum cheeb tsam yuav tsum tsis txhob tsawg tshaj li 50%.

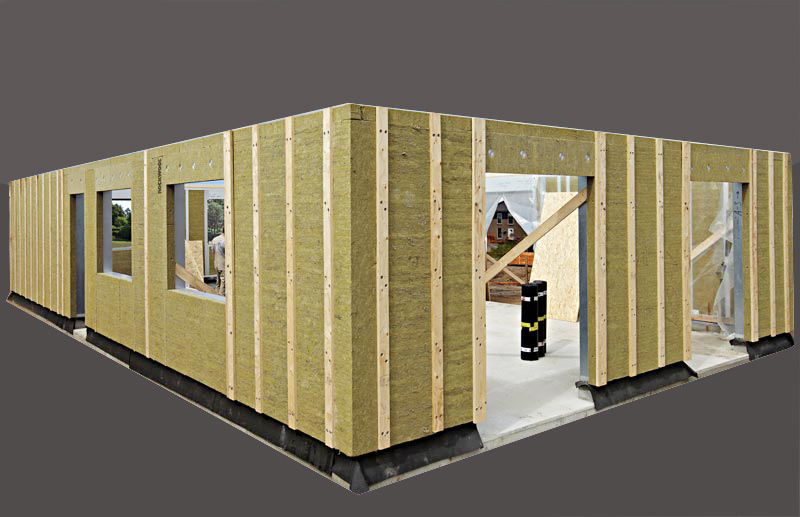

6. Tom qab lubpob zeb woolboard tiav nrog cov nplaum, qhov qis kawg ntawm cov rwb thaiv tsev yuav tsum tau pasted nrog lub hauv paus txheej.Covpob zeb woolboard yuav tsum tau pw horizontally los ntawm hauv qab mus rau sab saum toj, thiab sab nteg thiab anchoring txoj kev yuav tsum tau saws rau kho.Kaw ib txwm, thiab qhov sib txawv ntawm daim hlau yuav tsum tsis txhob ntau tshaj 2 hli.Yog hais tias lub seam dav yog 2 hli, nws yuav tsum tau ntim nrog cov ntaub ntawv rwb thaiv tsev thermal, cov laug cam uas nyob ib sab yuav tsum tau yaug, thiab qhov siab sib txawv ntawm cov laug cam yuav tsum tsis txhob ntau tshaj 1.5 hli.

7. Tag nrho cov phab ntsa pipelines thiab cov khoom uas tuaj yeem ncav cuagpob zeb wool board yuav tsum tau ntim nrog tib yam khoom ntawm qhov chaw tawm thiab tom qab ntawd yuav tsis muaj dej thiab kaw.Yog tias cov txheej txheem veneer pom tau poob tawm thaum lub sijhawm tsim kho, nws yuav tsum tau kho nyob rau lub sijhawm los ntawm kev sib txuas lossis kev thauj mus los nrog cov thauj tog rau nkoj, thiab txheej txheej veneer sab nrauv yuav tsum tau tsim nyob rau lub sijhawm.

Post lub sij hawm: Sep-17-2021